RACK JACK

It produces more sophisticated products with more advanced technology.

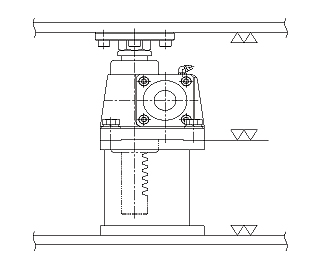

1) Machining of the mounting surface

- For more precise operation and leveling, the mounting surface of the power base should be machined before installation.

- After welding the frame structure, machine the mounting surface and proceed with assembly.

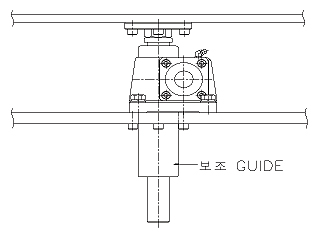

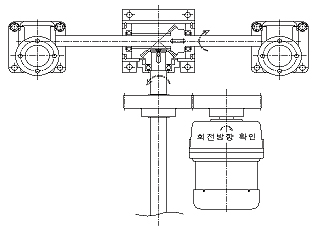

2) Attachment of Auxiliary Guide

- For strokes over 600mm, attaching an auxiliary guide helps minimize rack gear wobbling and reduce up/down errors.

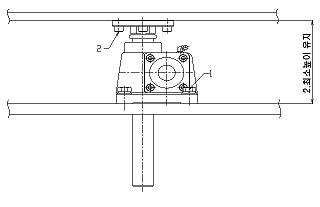

3) Flange Assembly in Down Position

- After bolting the gearbox section of the power base, the upper frame should be bolted while in the fully down position to minimize the load on the rack gear.

4) Adjusting Basic Height

- After assembling the rack jack, measure the overall basic height. If there are differences, adjust the height to match using the joints on the upper flange.

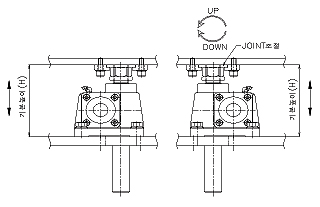

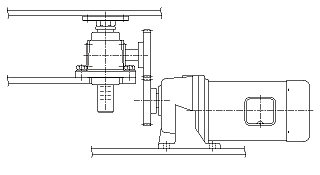

5) Bolt Fixation After Up/Down Test (Rack Jack Setting Method)

- After assembling the rack jack, check the motor's rotation direction. Loosen the upper and lower bolts slightly, perform repeated up/down tests, and then tighten the mounting bolts to complete the rack jack setting.

6) Spur Gear Driving Method

- For high-frequency use or more precise intermediate control, direct motor drive or gear-to-gear drive is more stable than chain drive.